Power Micro International Co.

New Technology to Extend Mold Life

The introduction of Japanese nano-lubricating ball powder, along with advanced technology, significantly reduces metal mold consumption.

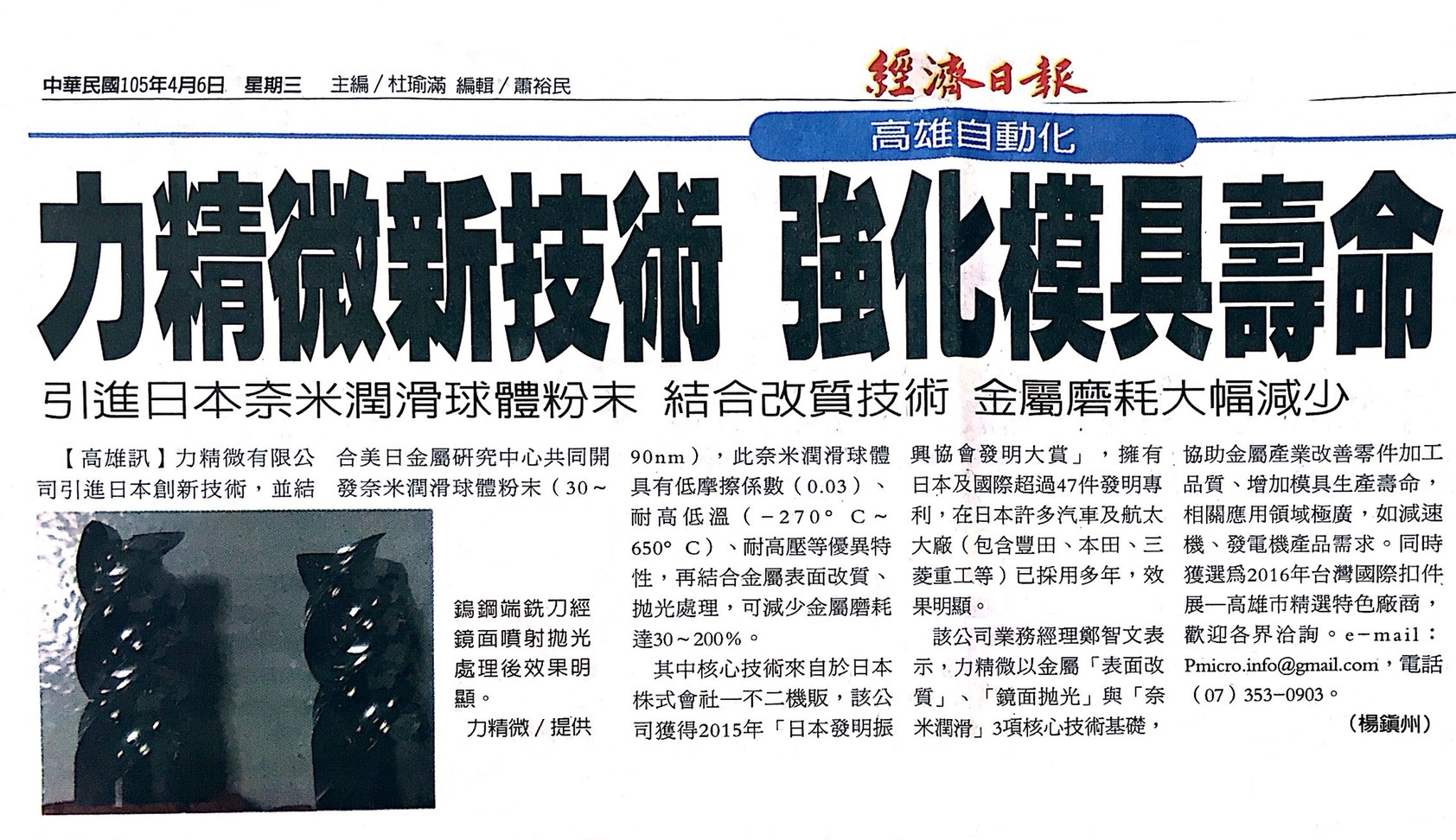

With the introduction of innovative Japanese technology and the collaborative efforts of the US-Japan Metal Research Center, nano-lubricating sphere powder (30–90 nm) exhibits a low friction coefficient of 0.03 and can withstand extreme temperatures ranging from -270°C to 650°C. This powder also demonstrates high pressure resistance and other exceptional properties. When combined with metal surface modification and polishing treatments, it can reduce metal mold consumption by as much as 30% to 200%.

Based on the three core technologies of metal surface modification, nano lubrication, and mirror polishing, Power Micro International helps the metal industry enhance the quality of parts processing and extend the lifespan of molds.

Taken from Yangzhenzhou (April 6, 105). Kaohsiung Automation. The Economic Times.