Technical Introduction

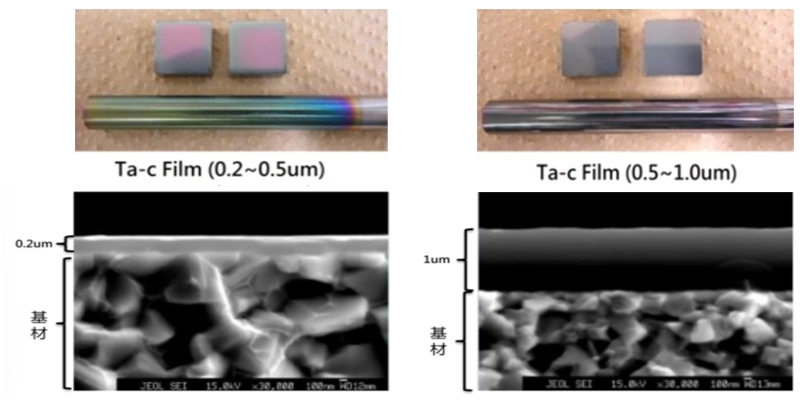

Using a specialized high-vacuum ion sputtering technique, carbon atoms are deposited onto the surface of the object in a diamond (sp³) structure. This is the only technology in the world capable of depositing an ultra-thin 100 nm coating at a low temperature of 150 degrees Celsius.

Characterized by high hardness, resistance to acids and alkalis, a smooth surface, a low friction coefficient, easy release properties, wear resistance, excellent thermal conductivity, and suitability for low-temperature processing, this material can be applied to molds and cutting tools for processing aluminum and copper alloys, as well as for protecting precision components made of tungsten steel and ceramic materials.

Coating Examples

▲Applicable to various semiconductor tools, molds, and cutting tools.

◆Ceramic surface coating for lubrication

◇Medical titanium alloy that is wear-resistant and lubricious

◆Medical molds that do not require release agents

◇Semiconductor parts that are wear-resistant

◆Used for PCB cutting tools

◇Semiconductor plastic cutting tools

◆High polymer plastic cutting tools

Features of SP³ Diamond Film

◎High-temperature resistance ◎Diamond hardness ◎Excellent electrical insulation ◎High film density ◎Good thermal conductivity ◎Outstanding wear resistance