Brief Introduction to Anti-Stick ( Lubricating Coating)

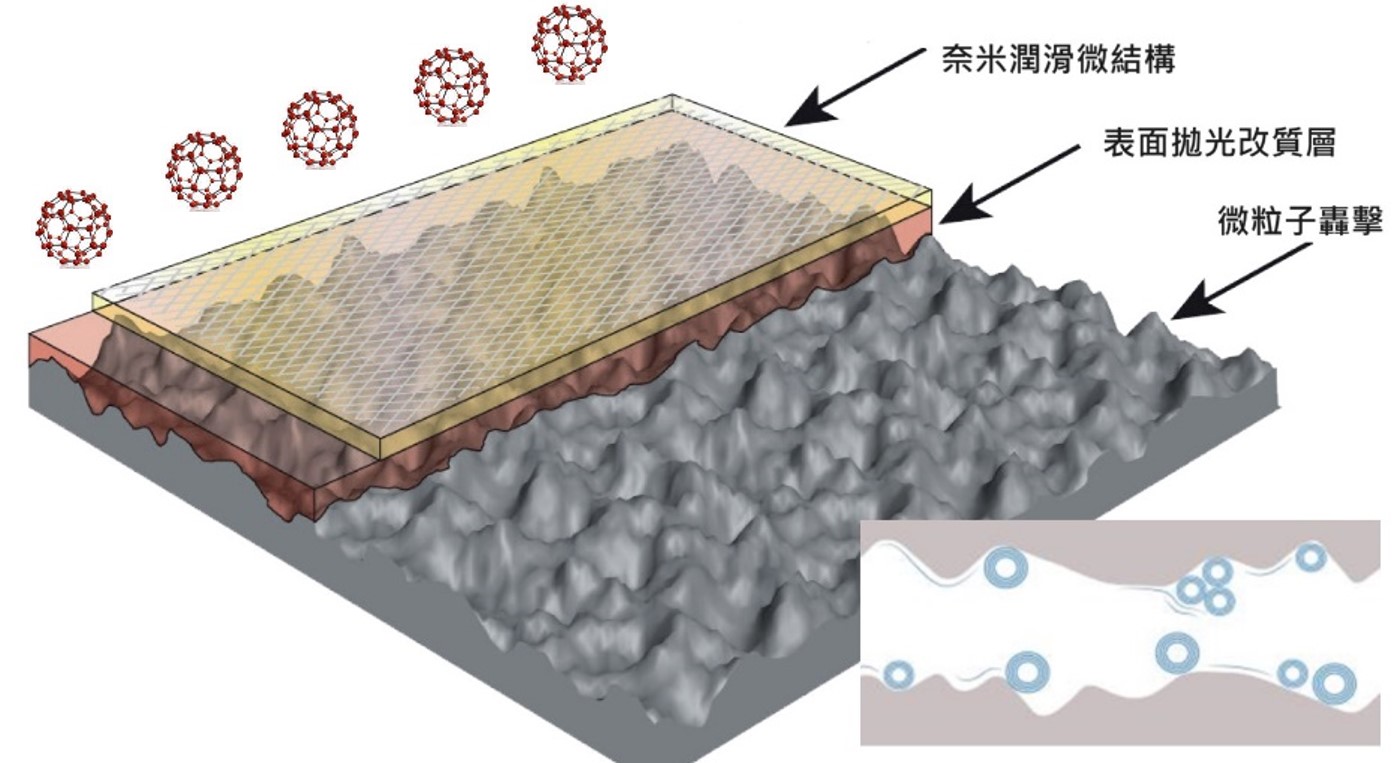

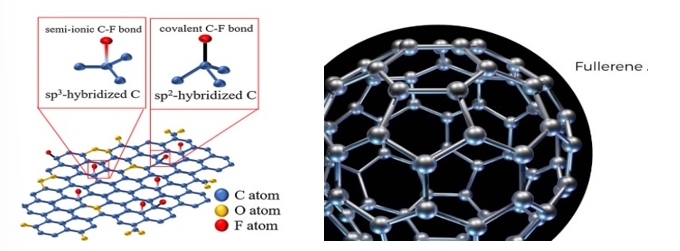

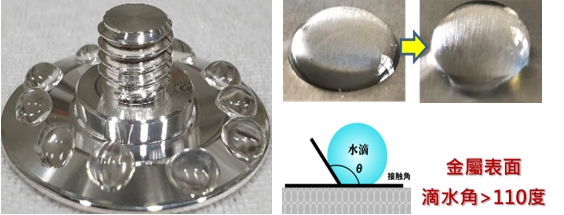

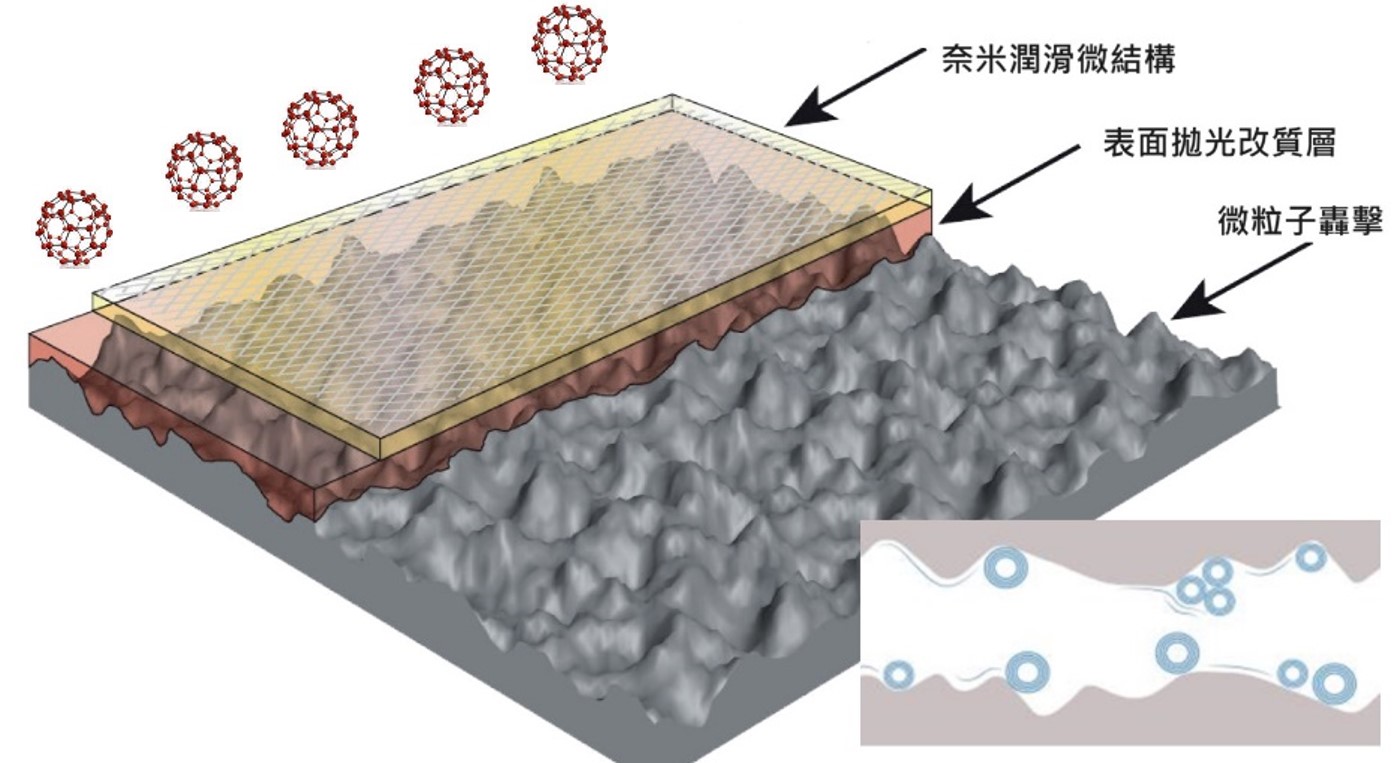

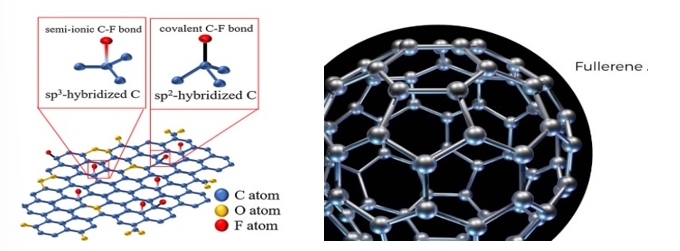

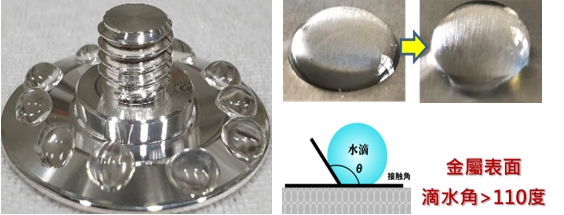

Key materials are sourced from the Weizmann Institute of Science in Israel. Fullerene (WS₂) and graphene (CFn) ion bombardment are employed to activate metal and ceramic surfaces. This process is followed by micro-particle surface modification to produce nanostructures, combined with surface techniques such as polishing, physical vapor deposition (PVD), nitriding, and carburizing. The resulting materials exhibit anti-stick properties and an ultra-smooth finish.

◆The primary benefits of "anti-stick" and "lubricating treatments

-

Packaging mold parts do not adhere to tin (Sn).

-

Lithium battery cutting tools do not adhere.

-

Medical injection molds do not require release agents.

-

Ultra-precision micro-hole nozzles are non-stick.

-

Optical film and TPU tungsten steel cutting tools do not adhere.

-

The components of the medical product packaging line do not adhere properly.

Introduction toAnti-stick (Lubricating Coating)

◆Film Property

-

Micro particle molecular CFn, WS₂

-

Modification thickness 0.2~0.5um

-

Surface friction coefficient <0.05

-

Surface Ra remains unchanged

-

Maximum use temperature 300 degrees

-

Processing temperature <100 degrees