High-Alkaline Electrolytic Ionized Water Generation Equipment Features

-

Generate alkaline electrolyzed ionized water with a pH of 13.2.

Due to its high concentration, only a small amount is required to adjust the pH, resulting in the lowest operating costs in the industry.

One day can produce up to 80 liters (equivalent to pH 12.5 in 400 liters).

-

No wastewater

No acidic water, chlorine, or wastewater is produced, eliminating the need to manage waste liquids and incur costs associated with waste treatment.

-

It is also easy to replace perishable items.

Easily replace consumable items without incurring replacement costs.

-

Environmental Protection

Electrolytes utilize environmentally friendly food additives and do not contain substances that harm the environment.

-

Press the on the touch panel to begin.

1. Add the additive and wait.

2.Then, simply mix the generated alkaline electrolyzed ionized water into the cutting fluid reservoir.

High-Alkaline Electrolytic Ionized Water Generation Equipment Application Scenarios

-

Grinding Machine

-

Lathe

-

Gear Hobbing Machine

-

CNC

-

Prolong the lifespan of grinding wheels and tools while enhancing processing efficiency to boost productivity.

-

Reduction in cutting oil concentration and refill leads to a decrease in cutting oil usage.

-

The lifespan of cutting fluid is extended to prevent contamination, minimize waste oil, and reduce costs.

-

The temperature of the cutting fluid decreases, which extends the life of the equipment.

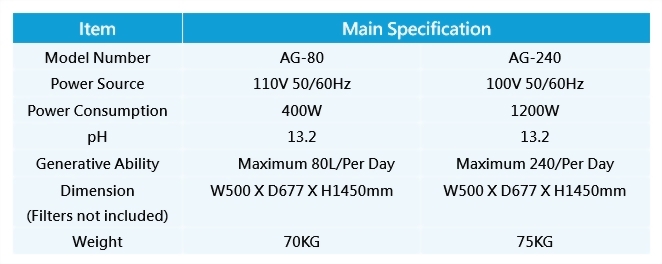

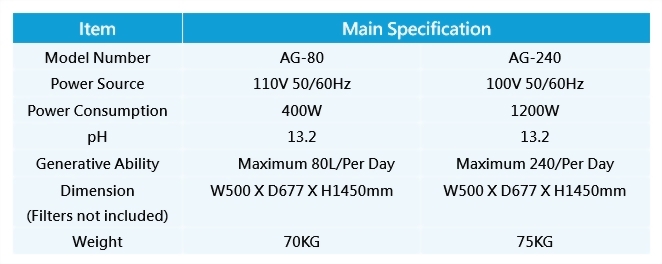

High-Alkaline Electrolytic Ionized Water Generation Equipment Specification

-

A device the size of a refrigerator conserves space.