Introduction to Fullerene Nanotechnology (IF-WS₂ Fullerene)

Dr. Reshef Tenne, an expert in international nanoscience, invented the world's most lubricious nanoballs, known as IF-WS₂ fullerenes, and has been nominated multiple times for the Nobel Prize in Chemistry.

In 2012, Dr. Tenne co-founded NIS, a company in collaboration with a U.S. venture capital fund and the Department of Defense, specializing in the global sale of lubricating oil materials.

Power Micro International Company was established to minimize production friction issues and enhance the lifespan of cutting tools and molds as part of its service mission.

Actively collaborating with government metal research units to integrate essential foreign technologies into the machinery and mold industry, thereby enhancing the surface quality of production components and significantly extending the lifespan of molds.

Currently, it serves as the general agent for NIS Fullerene Nano Lubricating Oil in Taiwan, Japan, and China.

Technical Features of Fullerene Nanostructures (WS₂)

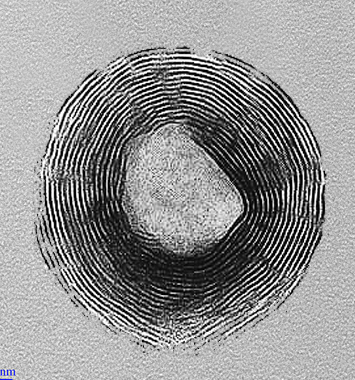

▲The nanoparticles have a diameter of approximately 10 to 80 nanometers and a shell structure consisting of 10 to 20 layers.

▲Non-toxic in biological testing and safety certified.

▲Awards Received Over the Years

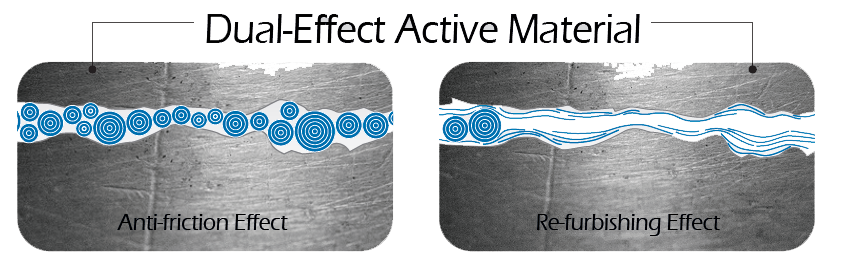

▲Fullerene (IF-WS₂) autonomously generates a lubricating film on metal surfaces.

Usage of Fullerene (IF-WS₂)

Directly incorporate into the lubricating oil utilized in the current production process.

Application Scenarios for Fullerene (IF-WS₂)

Application Case of Fullerene (IF-WS₂): Enhancing Lubrication in Cold Forging Dies and Improving Mold Anti-Adhesion

▲The comparison between the first photo (before) and the second photo (after) shows that the outer surface of the screw achieves a near mirror finish following the addition of nano balls.

Application Case of Fullerene (IF-WS₂): Extending Tool Life and Preventing Tool Adhesion

Nanosphere Additive for Tool Protection Mechanisms:

The only nanomaterial that can be directly added to cutting fluids forms a nanolubricating film on the tool during the intense friction of the machining process, preventing adhesive wear when the tool contacts the material.

Using the Japanese UNION TOOL and the Swiss DIXI End Mill::

▲Swiss DIXI Polytool S.A. and Japanese UNION Tool are both globally recognized leaders in the tool industry, and it is quite challenging to enhance the lifespan of their tool products.

▲The tool life of high-speed steel workpieces is increased by 220%, and the surface roughness (Ra) of high-speed steel milling is significantly reduced.

▲HSB Milling Cutter

Nano Ball Extreme Pressure Lubrication - Industrial Products

Introduction Video

Nano Ball Extreme Pressure Lubrication - Cooperative Research Products

Nanotechnology is redefining our understanding of the world.

We continue to uncover new opportunities by integrating nanoparticles with other products that we have been using for years.

If you would like to propose a collaboration idea, please explore the nano products in this category and reach out to us!

Micro Particle Modification Technology combined with Nano Ball Lubrication results in "Unimaginably Low Friction."

Introduction Video